Understanding the Core Materials Used in Advanced PCB Structures

Printed Circuit Boards (PCBs) are the lifeline of modern electronics. As devices become faster, smaller, and more complex, the materials used in PCBs have evolved significantly to meet these demands. Today, advanced PCB structures are no longer limited to simple copper and fiberglass composites. Instead, they incorporate innovative materials that enhance performance, durability, and heat management. This article delves into the core materials used in advanced PCB structures, offering insights into their roles, benefits, and applications in modern electronics.

The Evolution of PCB Materials

Originally, PCBs were made with simple materials like phenolic resin and standard fiberglass (FR-4). These materials were sufficient for basic applications, but as technology progressed, they struggled to keep up with high-speed and high-frequency demands. The shift toward advanced PCB materials was driven by several factors:

- Miniaturization of electronic devices- Higher circuit densities

- Greater thermal management needs

- Improved electrical performance

Manufacturers and engineers had to seek out materials that could provide better mechanical strength, thermal stability, and electrical reliability.

Importance of Material Selection in PCB Design

Before exploring specific materials, it’s essential to understand why material selection is crucial in PCB design. The performance of a PCB is highly dependent on its base materials, which influence:

- Signal integrity- Thermal management

- Mechanical durability

- Manufacturing complexity

- Cost efficiency

For high-speed circuits, for example, materials with low dielectric constants and minimal signal loss are preferred. For power electronics, excellent thermal conductivity is non-negotiable.

Advanced PCB Materials: Types and Characteristics

In this section, we explore the most commonly used materials in advanced PCB structures and why they matter.

1. High-Frequency Laminates

High-frequency laminates are essential for applications involving radio frequency (RF) and microwave circuits. These materials provide:

- Low dielectric constant (Dk)- Low dissipation factor (Df)

- Stability across temperature variations

Materials like PTFE (Polytetrafluoroethylene), ceramic-filled PTFE, and hydrocarbon ceramics are popular choices for high-frequency PCBs. These laminates ensure minimal signal loss, making them suitable for communication devices and aerospace applications.

2. Polyimide Substrates

Polyimide offers excellent thermal stability and mechanical strength, making it a preferred material in harsh environments. Its benefits include:

- High thermal resistance- Flexibility (used in flexible PCBs)

- Excellent chemical resistance

Polyimide is commonly used in the automotive industry, military applications, and advanced medical devices where reliability is critical.

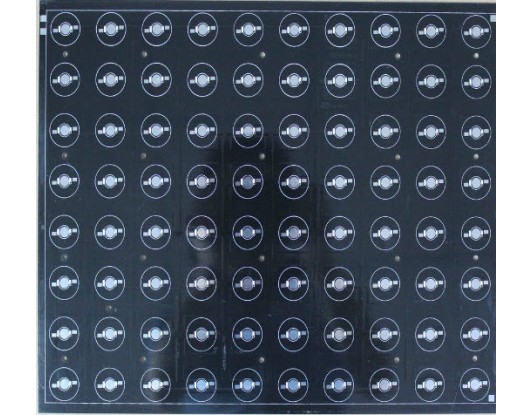

3. Metal Core PCB Materials

Metal core PCBs are gaining popularity due to their superior heat dissipation properties. Typically, these PCBs use an aluminum or copper base layer beneath the insulating dielectric material. This construction allows for:

- Efficient thermal management- Enhanced durability

- Reduced risk of overheating in high-power applications

Metal core PCB designs are ideal for LED lighting systems, power supplies, and automotive electronics, where heat control is paramount.

4. Ceramic PCBs

Ceramic PCBs utilize ceramic substrates like alumina or aluminum nitride, known for:

- Exceptional thermal conductivity- High mechanical strength

- Low coefficient of thermal expansion (CTE)

These properties make ceramic PCBs suitable for high-power devices, aerospace technology, and industrial controls requiring robust thermal performance.

5. Aluminum Substrate PCB

An Aluminum substrate PCB is a specialized type of metal core PCB that focuses on leveraging aluminum’s natural thermal conductivity and lightweight properties. These boards:

- Provide excellent heat dissipation- Improve mechanical stability

- Are cost-effective compared to other metal core options

They are extensively used in LED technology, automotive lighting systems, and power converters, where maintaining low operating temperatures is critical.

Factors to Consider When Choosing PCB Materials

Selecting the right material for your PCB design is not just a technical choice but a strategic decision that affects performance, manufacturing, and longevity. Here are some key considerations:

1. Thermal Management

For high-power applications, effective heat dissipation is essential. Materials with high thermal conductivity, such as metal cores or ceramics, are beneficial.

2. Electrical Performance

High-frequency or high-speed circuits require materials with low dielectric constants and minimal signal loss.

3. Mechanical Strength

For devices exposed to vibrations, shocks, or mechanical stress, durable materials like polyimide or metal core laminates provide the necessary resilience.

4. Environmental Resistance

Harsh environments demand materials that can withstand moisture, chemicals, and temperature fluctuations.

5. Cost and Availability

Advanced PCB materials can be expensive. Balancing performance needs with budget constraints is vital for cost-effective design.

The Future of Advanced PCB Materials

As technology continues to advance, so does the innovation in PCB materials. Emerging trends include:

- Development of eco-friendly materials to support sustainable electronics manufacturing- Enhanced hybrid materials combining the benefits of ceramics and metals

- Increasing use of nanomaterials to improve electrical and thermal properties

Manufacturers are also investing in research to create materials that support higher data transfer rates and improved energy efficiency. These advancements will play a pivotal role in next-generation technologies such as 5G infrastructure, electric vehicles, and advanced medical equipment.

Conclusion

Understanding the materials used in advanced PCB structures is critical for anyone involved in electronics design and manufacturing. From high-frequency laminates to metal core and aluminum substrate PCB technologies, each material offers unique benefits tailored to specific applications. By selecting the right combination of advanced PCB materials, engineers can ensure optimal performance, reliability, and efficiency for their projects.

As the demand for faster, more powerful, and more durable electronic devices grows, staying informed about the latest developments in PCB materials is not just advantageous — it’s essential. Whether you’re designing for aerospace, automotive, or consumer electronics, the right materials can make all the difference.